Injection moulding production

Injection moulding is one of the most common methods of forming plastic materials. This is a process where the heated plastic is injected into moulds prepared for this purpose. The popularity of the technology stems from the possibility of its easy use in serial production and in the successful achievement of strict customer tolerances at low production costs.

Technology and production:

1. We operate thirteen modern injection moulding machines.

2. The closing forces of the machines are from 1500kN to 8000 kN.

3. For safe and fast handling of injection moulded products, we have robots and belts on all injection molding machines for automatic removal of products from injection moulding tools.

4. For the purpose of stabilization and cooling of products, we have special shelves.

5. We mostly use PP and PE materials.

6. The injection moulding process is adaptable to a wide range of materials. It is also possible to make products from recycled material (“environmentally friendly production”).

7. We produce products from 18g to 2300g.

8. We use IML technology, which allows us to integrate stickers according to the wishes of customers on buckets: 2 l, 5 l, 11 l, 12 l and 18 l.

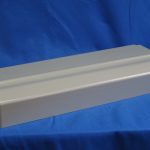

Blow moulding production

Blow moulding is the process of making hollow objects by blowing air into a piece of plastic, so that it spreads along the inner walls of the mould. Plastic blowing technology is one of the fastest growing plastics processing technologies today as it offers optimal speed, production of quality hollow finished products at low production costs. Currently, there is no other plastic shaping process that would offer such a wide range of products as blowing.

Technology and production:

1. In our production unit in Kanal we operate 8 blowing machines.

2. With the existing machines we can offer the service of blow moulding for production of a wide range of different hollow products from 0.5 l to 150 l (fuel jerrycans, loading containers, barrels, bottles,etc.).

3. Products are made of HDPE material.

4. At the customer’s request, products can also be produced from recycled material (“environmentally friendly production”).

5. We offer our customers the services of internal product testing, advice and assistance in obtaining UN certificates.

6. To complete the finished product, we offer our customers the service of manual assembly. With the help of simple preparations, we perform manual assembly, screwing, “click” assembly, for our own products.

Custom services

In our production we can fulfil any wish of our customers:

1. We have 50 years of experience in the field of plastic injection moulding technology and 40 years of experience in the field of blow moulding technology.

2. Our experienced professionals develop the technology and products that we use in production of high-quality products tailored to the customer.

3. With our plastic injection and blow moulding machines, we can respond to the requirements of customers operating in various industries.

4. Based on many years of experience, our company, in cooperation with external suppliers, offers fast and efficient production of the tools you need for your dream product, and we also offer solutions and development of the product itself.

5. We are ready to listen to each customer, treat him individually and make his wishes come true to the greatest extent.

6. We also give advice on optimizing products and processes to reduce costs while ensuring the same product quality.

7. We offer comprehensive support from the concept to final product.

Custom made products:

For more information about custom made products or services please contact us on the email: [email protected].